We’ve turned up the HEAT on our V5 range.

Introducing HotMelt XT — our advanced resin, pushed beyond 260°C to reduce viscosity to the extreme. The result? Seamless saturation of every single carbon fibre strand.

This means:

Total resin coverage

Maximum structural integrity

Zero voids

A feel like no other

The V5 range isn’t just an upgrade — it’s our most refined and responsive TC line up yet, setting a new gold standard in custom racket manufacturing.

Hotter resin. Void-free flow. Perfection, engineered.

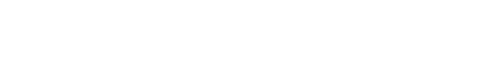

HOT MELT XT

We’ve turned up the heat — literally.

By raising the temperature of our raw materials, we’ve lowered the viscosity of the resin used to coat our High Modulus carbon fibres. The result? Flawless flow, deeper saturation, and what we call Total Coverage.

Or as we like to say: Perfection Manufacturing.

This is the foundation of our V5 Tennis Rackets — the most precise, responsive, and refined models we’ve ever built.

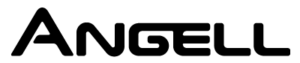

MICRO BRAID

Shaped by heat. Defined by pressure.

Our carbon frames are moulded under intense heat and pressure to ensure optimal strength and precision. At the heart of this process lies our MICRO BRAID layer — engineered to minimise resin flow out of the structure.

The result? A more consistent frame, enhanced structural integrity, and a higher-performing racket every time.

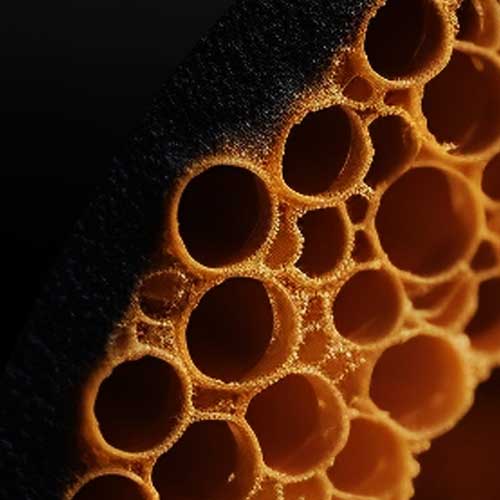

FOAM CORE

Solid to the core.

All Angell custom models are filled with our proprietary Foam Core, delivering exceptional dampening and the unmistakable feel of a solid, filled frame.

It’s this unique construction that gives every Angell racket its signature sensation — controlled, comfortable, and confidently precise.

OPTIONS GALORE

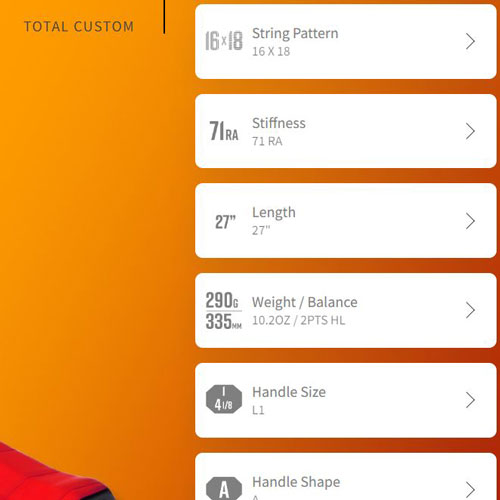

A custom tennis racket is more than just a paint job. Define your exact frame specifications with our online racket configurator